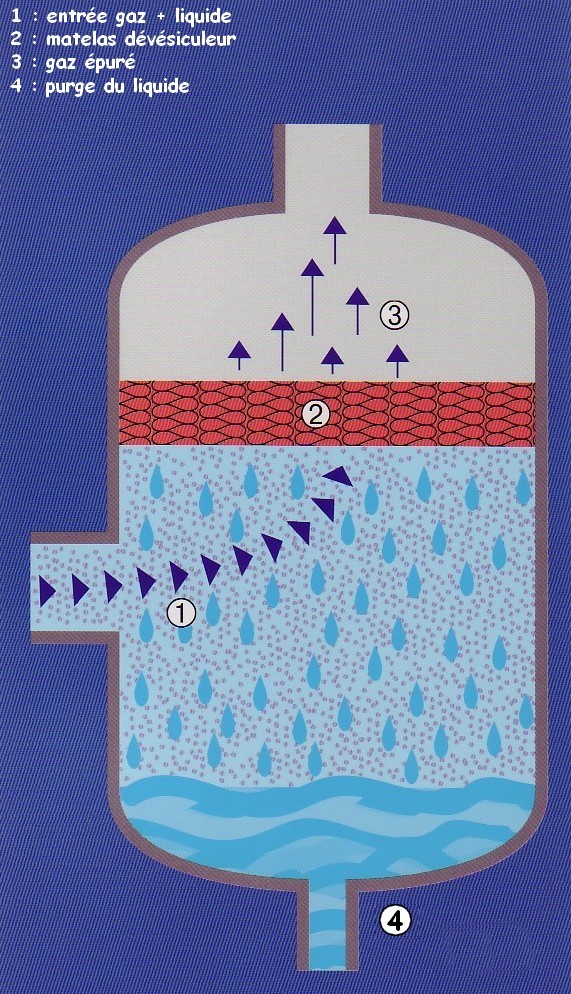

Applications :

Gas - Liquid Separation (by example air / solvent) with

porous blanket of wire knitted mesh, or with separator and/or coalescing cartridges.

Degree of Separation :

Since the

kinetic energy of a droplet is determined by its velocity and mass, it is obvious that droplet size in an important factor in separation efficiency.

With a “normal bell curve” distribution it can be expected a separation

efficiency from 98% to 99.9% using a 6’’ thick mist eliminator.

Service Pressure:

150 & 300 lbs

Flow rate :

Separator exist with in/out diameter from 1’’ to 20’’.

Separation process :

Droplets are formed from a saturated vapor, and a random size distribution usually results. As gas

flows through the mesh pad the flow streamline are defected by the wires. The inertia of the liquid droplets will be normally too high for them to follow the streamline and they impinge on the wires.

Advantages :

Low pressure drop ( < 2 inches water )

No moving part

High reliability.

Fabrication in carbon steel, 304 L or 316 L stainless steel,

According ASME VIII div 1 code.

Minimum required data for inquiry:

Type of fluid (gas and liquid)

% of liquid (in weigh) in the flow.

application.

flow capacity.

pressure.

Demister / Scrubbers

Scrubber Gas liquid separator